PE Ro 3840 UA antibacterial

PE Ro 3840 UA antibacterial

Rotational grade polyethylene compound is a combination of best quality rotation polymer and color additives (titanium dioxide or colored pigment) as well as an antibacterial additive in accordance with the standard and with the necessary approvals in the form of powder with a maximum powder size of 800 microns with suitable powder dispersion for rotational molding.

PE Ro 3840 UA antibacterial

ompound is a combination of best quality rotation polymer and color additives (titanium dioxide or colored pigment) in the form of powder with a maximum powder size of 800 microns with suitable powder dis

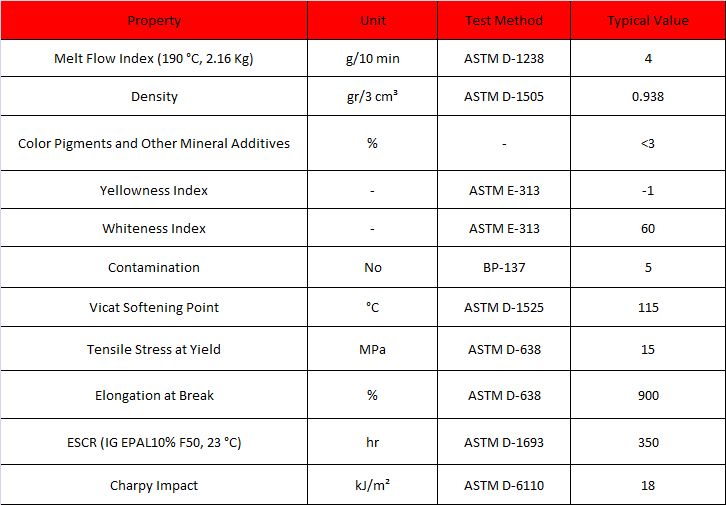

Compound 3840 Yellow Specifications

PROPERTY:MELT FLOW INDEX (190 °C, 2.16 Kg)

UNIT:g/10 min TEST METHOD:ASTM D-1238 TYPICAL VALUE:4

PROPERTY:DENSITY

UNIT:gr/3 cm TEST METHOD:ASTM D-1505 TYPICAL VALUE: 0.938

PROPERTY:Color pigments and other mineral addetives

UNIT:% TEST METHOD:- TYPICAL VALUE:<3

PROPERTY:YELLOWNESS INDEX

UNIT:- TEST METHOD:ASTM E-313 TYPICAL VALUE:-1

PROPERTY:WHITENESS INDEX

UNIT:- TEST METHOD:ASTM E-313 TYPICAL VALUE:60

PROPERTY:CONTAMINATION

UNIT:No TEST METHOD:BP-137 TYPICAL VALUE : 5

PROPERTY:VICAT SOFTENING POINT

UNIT:°C TEST METHOD:ASTM D-1525 TYPICAL VALUE 115

PROPERTY:TENSILE STRESS AT YEILD

UNIT:MPA TEST METHOD:ASTM D-638 TYPICAL VALUE: 15

PROPERTY:ELONGATI N AT BREAK

UNIT:% TEST METHOD:ASTM D-638 TYPICAL VALUE: 900

PROPERTY:ESCR(I G EPAL10% F50,23 C)

UNIT:HR TEST METHOD:ASTM D-1693 TYPICAL VALUE: 350

PROPERTY:CHARPY IMPACT

UNIT:Kj/M2

TEST METHOD:ASTM D-6110

TYPICAL VALUE: 18 persion for rotational molding.