Compound production 3840

In recent years, environmental pressures, international regulations, and customer expectations have pushed the polymer industry toward more sustainable production. Companies producing polyethylene compounds, including Sabico, are at the heart of these changes. This article explores strategies for reducing the carbon footprint in the production of Compound 3840, the feasibility of recycling PE compounds, and the use of biodegradable materials in rotomolding.

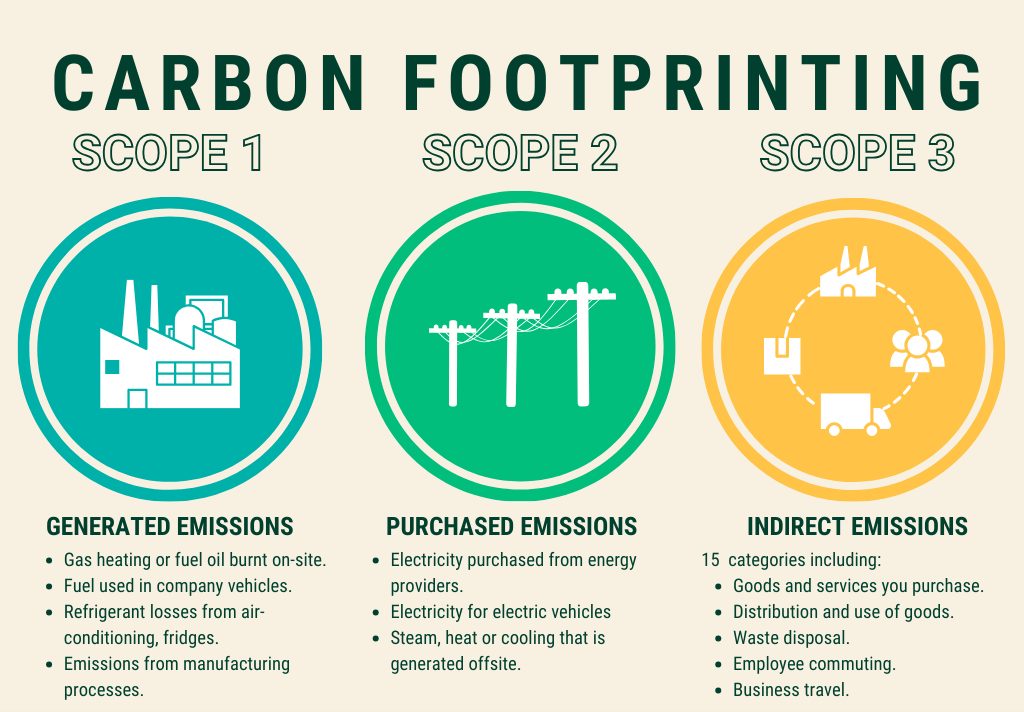

What is Carbon Footprint and Why Should It Be Reduced?

The carbon footprint refers to the amount of greenhouse gases—especially carbon dioxide—released into the environment during a product’s life cycle, from production to disposal or recycling. In petrochemical and polymer industries, the footprint includes:

Energy consumption during manufacturing

Use of fossil-based raw materials

Transportation of goods

Waste generated during the process

Reducing the carbon footprint helps protect the environment. It also serves as a significant competitive advantage for companies operating in global markets.

How to Reduce the Carbon Footprint in the Compound production 3840 of PE

Compound production 3840 is widely used in manufacturing polyethylene tanks, drums, and rotomolded parts. To reduce its environmental impact, several core strategies are available:

1. Using Renewable Energy in Manufacturing

Switching to renewable sources such as solar or wind energy in production lines can reduce CO₂ emissions by up to 40%.

2. Optimizing Formulations to Minimize Waste

Accurate formulation using advanced material-blending software can minimize production waste. Additives that improve processing efficiency also reduce energy consumption.

3. Incorporating High-Quality Recycled Materials

Incorporating a percentage of high-quality post-consumer recycled (PCR) polyethylene can reduce environmental impact—provided that the final product retains its mechanical and chemical properties.

4. Installing Filtration and Heat Recovery Systems

Equipment that filters emissions and recovers heat not only protects the environment but also improves energy efficiency.

In-Factory Recycling of PE Compound production 3840: Challenges and Opportunities

Recycling post-consumer or production scrap materials is a key element of sustainable production. Polyethylene has high potential for recycling, especially when contamination or incompatibility is avoided.

Compound production 3840

Advantages of Recycling in Compound production 3840:

Reduces raw material costs

Minimizes industrial waste

Improves brand image among environmentally-conscious customers

Challenges:

Mechanical property degradation after multiple recycling cycles

Need for precise separation of colored or additive-laden scraps

Technical limitations in using recycled materials for sensitive applications (e.g., drinking water barrels)

Solutions:

Using modern separation technologies, combining recycled materials with virgin PE, and continuous quality testing are effective strategies for integrating recycling into production.

Biodegradable Alternatives in the Rotomolding Process

Rotomolding is a low-pressure and versatile process that allows the use of various materials. Although polyethylene (such as Compound 3840) is the most common, recent efforts have explored biodegradable or compostable alternatives.

Compound production 3840

Potential Biodegradable Options:

1.PLA (Polylactic Acid): A plant-based polyester (corn, sugarcane) that is biodegradable under certain conditions.

2.PHA (Polyhydroxyalkanoates): A bio-polymer produced by bacteria, decomposable in soil or marine environments.

3.Bio-composites: A mix of natural polymers and plant-based fibers (e.g., hemp, bamboo, wood) for lightweight and strong components.

Limitations:

Different melting temperatures and thermal behavior compared to PE

Higher production costs

Shorter lifespan in humid or high-stress environments

For disposable or pilot-use components, these materials offer a more sustainable future for rotomolding.

Conclusion: A Sustainable Future for the Polymer Industry Requires Action

Companies like Sabico can play a vital role in reducing the environmental footprint of the plastics industry. Through advanced formulation, investment in sustainable equipment, and a move toward a circular economy, they can lead this transition. Reducing the carbon footprint in the Compound production 3840 is just one step. Expanding recycling and adopting biodegradable materials are essential to shaping a sustainable future.