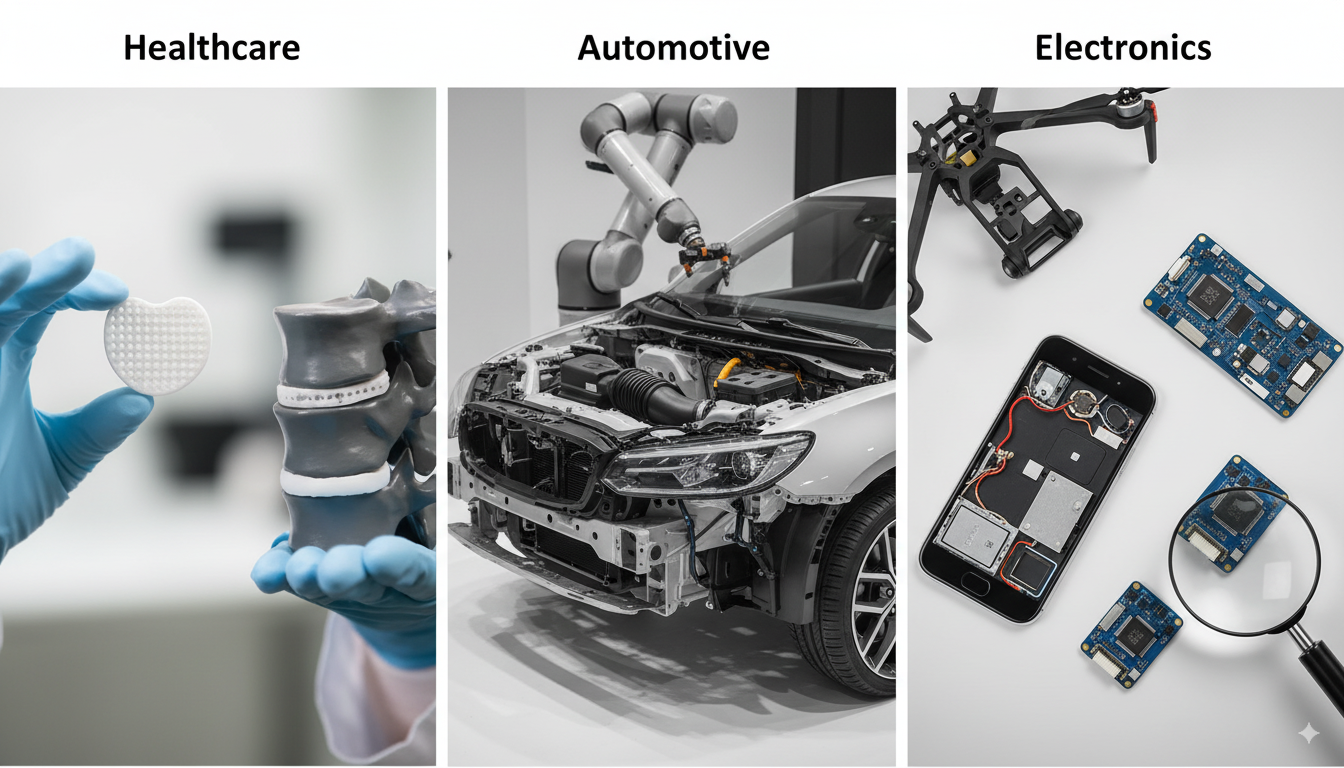

Engineering polymers have evolved far beyond their traditional uses. Today, they play a central role in high-performance sectors such as healthcare, automotive, and electronics. These industries demand materials that offer durability, precision, and versatility. Thanks to continuous innovation, engineering plastics now meet—and often exceed—those expectations.

Let’s explore how these advanced materials are transforming key industries, one application at a time.

1. Healthcare: Enhancing Safety, Functionality, and Design

The healthcare sector faces strict requirements for hygiene, safety, and reliability. As a result, materials used in medical devices must meet high standards for biocompatibility and sterilization resistance. Engineering polymers meet these challenges with ease.

Engineering polymers such as PEEK and PPSU are widely used in surgical tools due to their strength and resistance to sterilization. These materials not only withstand repeated autoclaving but also resist aggressive disinfectants without degrading.

Moreover, implants and prosthetics benefit from materials like UHMWPE and medical-grade PEEK. These polymers are lightweight, chemically stable, and radiolucent—making them especially suitable for spinal cages, joint replacements, and cranial implants.

In addition, diagnostic equipment often relies on polymer components. Their non-magnetic properties make them ideal for use in MRI machines, CT scanners, and other sensitive imaging systems.

Furthermore, the rise of single-use medical devices has created a growing demand for polymers that are safe, affordable, and easy to process. These materials support faster production and lower infection risks.

2. Automotive: Driving Lightweight Innovation

The automotive industry continues to seek ways to reduce vehicle weight, improve fuel economy, and lower emissions. Consequently, automakers are replacing metal parts with engineering polymers—strong, lightweight materials that improve performance and efficiency.

For instance, under-the-hood components such as air intake manifolds, valve covers, and cooling system parts now often use engineering polymers like glass-reinforced PA66 (Nylon 66). These materials handle high heat and mechanical stress while cutting weight significantly.

Meanwhile, the shift to electric vehicles (EVs) brings new opportunities for engineering polymers. Materials such as PBT (Polybutylene Terephthalate) and PC (Polycarbonate) are now used in battery housings and insulation systems, offering flame retardancy and high impact resistance.

Additionally, interior and exterior parts—including dashboards, trim panels, and bumpers—benefit from engineering polymers like ABS, TPU, and PP blends. These polymers allow for greater design freedom and improved manufacturing efficiency.

Ultimately, replacing metal with engineering polymers can reduce the weight of certain components by 30–50%. This results in better vehicle range for EVs and improved fuel efficiency in traditional vehicles.

3. Electronics: Supporting Miniaturization and Performance

In electronics, materials must handle tight spaces, high temperatures, and sensitive electrical environments. Engineering polymers excel under these conditions.

To illustrate, manufacturers use LCP (Liquid Crystal Polymer) and PBT in high-density connectors, switches, and sockets. These polymers offer flame resistance, heat stability, and excellent dimensional accuracy.

Similarly, polyimide (PI) plays a vital role in flexible printed circuit boards. Found in smartphones, wearables, and aerospace electronics, PI offers flexibility and thermal resistance.

As devices become more powerful, managing heat is increasingly critical. Some engineering polymers now feature thermal conductivity enhancements, allowing them to transfer heat away from key components like LEDs and battery modules—while still offering electrical insulation.

Notably, certain advanced plastics provide EMI shielding, which is crucial in environments where electromagnetic interference can disrupt performance.

4. Sustainability and Advanced Manufacturing: A Competitive Edge

Beyond performance, engineering polymers also support sustainability goals. Manufacturers can now choose recyclable, bio-based, or ultra-durable materials to reduce environmental impact.

Moreover, these polymers integrate well with modern manufacturing technologies, including:

Injection molding, which supports high-speed, mass production

3D printing, ideal for rapid prototyping and complex geometries

Overmolding, allowing integration of polymers with metal or electronic components

As a result, companies can innovate faster, reduce part count, and lower production costs—while delivering high-quality products.

Conclusion: The Future Is Engineered

Engineering polymers have become essential to progress in healthcare, automotive, and electronics. They offer a unique blend of strength, flexibility, and functionality that traditional materials simply can’t match.

Looking ahead, we can expect even more breakthroughs—such as smart polymers, self-healing materials, and sustainable formulations. These innovations will continue to push the boundaries of what’s possible in design, manufacturing, and performance.

For companies seeking reliable, high-performance materials that meet today’s technical and environmental demands, engineering polymers are not just an alternative—they are the future