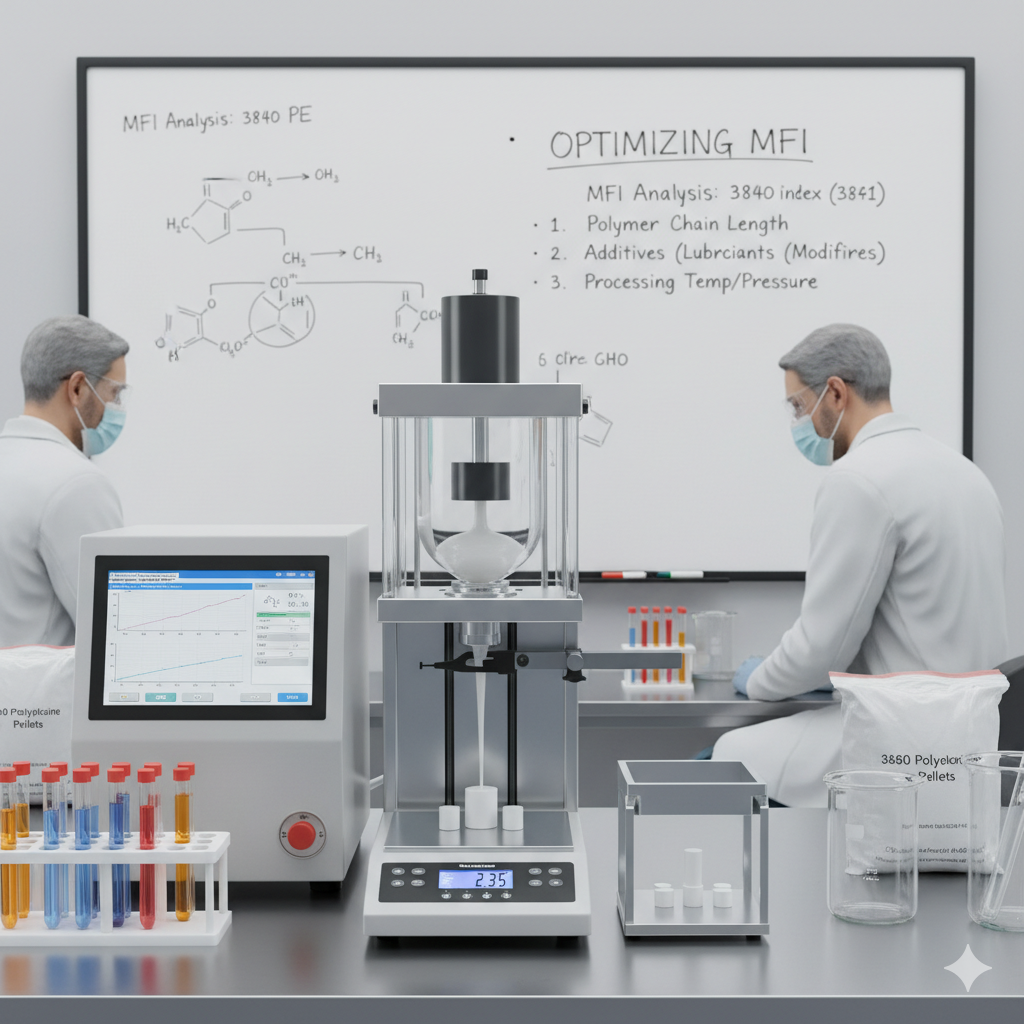

In the rotational molding (rotomolding) industry, the performance and processability of polyethylene compounds play a vital role in determining the quality and durability of final products. One key property that significantly influences the production process is the Melt Flow Index (MFI). Specifically, in high-performance grades like 3840 polyethylene compounds, controlling and optimizing the MFI is crucial—especially under high-temperature conditions where thermal stability and flow behavior become critical factors.

In this article, we will explore the importance of MFI in polyethylene compounds, the challenges of working with 3840 at elevated temperatures, and practical strategies to optimize MFI for better processing and final product performance.

What Is Melt Flow Index (MFI) and Why Does It Matter?

MFI is a measure of the flowability of a thermoplastic polymer when it is melted. Expressed in grams per 10 minutes (g/10 min), it indicates how easily the polymer will flow under a specific temperature and load, typically tested at 190°C or 230°C depending on the polymer type.

In the case of 3840 polyethylene compounds—commonly used for large, hollow parts in rotomolding—an optimal MFI ensures:

1. Efficient filling of the mold

2. Uniform wall thickness

3. Minimal internal stress

4. Balanced cycle times

An MFI that is too low can result in poor flow, incomplete molding, or longer processing times. Conversely, an excessively high MFI can lead to weak mechanical properties, deformation, or surface defects in the final product.

Typical Melt Flow Index Range for 3840 Polyethylene Compounds

3840 is a high-density polyethylene (HDPE) grade designed for demanding applications such as water tanks, containers, and technical parts. It generally features:

1. MFI Range: 7 to 9 g/10 min (at 190°C/2.16kg)

2. Density: 0.938 to 0.942 g/cm³

3. Excellent ESCR (Environmental Stress Crack Resistance)

4. High impact resistance and UV stability

This range of MFI provides a balance between processability and mechanical strength. However, even within this ideal range, minor fluctuations can cause significant changes in behavior during high-temperature processing.

High-Temperature Challenges in Rotational Molding

Rotational molding is a no-pressure, high-temperature process that relies on even heating and cooling of polymer powders inside a rotating mold. The typical processing temperature for 3840 compounds ranges between 220°C to 260°C.

At elevated temperatures, several challenges arise:

1. Thermal Degradation

Polyethylene begins to degrade if exposed to excessive heat for prolonged periods. This results in:

– Reduced molecular weight

– Increase in MFI beyond acceptable limits

– Formation of bubbles, voids, and weak zones

2. Inconsistent Flow Behavior

Uneven heating or rapid temperature rises can cause sudden spikes in Melt Flow Index, which affect flow uniformity and wall distribution, especially in thick-walled or complex parts.

3. Loss of Mechanical Properties

Higher MFI at elevated temperatures typically indicates lower molecular weight, leading to:

– Reduced tensile strength

– Poor impact resistance

– Deformation under load

Strategies to Optimize and Control Melt Flow Index in 3840 Compounds

To ensure consistent processing and maintain mechanical integrity in the final parts, manufacturers can apply the following strategies:

1. Use of Thermal Stabilizers

Adding antioxidants and thermal stabilizers such as hindered phenols, phosphites, or thioesters can:

– Prevent oxidative degradation

– Maintain consistent molecular weight

– Stabilize MFI during processing

2. Tailored Molecular Weight Distribution

Designing the compound with a narrow molecular weight distribution ensures more predictable flow behavior. A tighter distribution helps reduce variation in MFI across batches and enhances thermal stability.

3. Processing Temperature Control

Precise control of oven temperature and heating time is essential. Avoiding overheating or prolonged dwell times helps:

– Minimize thermal decomposition

– Maintain consistent MFI within the mold

– Reduce energy costs

4. Addition of Flow Modifiers

In some cases, flow enhancers or lubricants (e.g., polyethylene wax, silicone-based additives) are introduced to adjust MFI. However, overuse may:

– Weaken mechanical properties

– Create surface defects or exudation

Thus, dosage and compatibility must be carefully evaluated.

5. Consistent Pre-drying of Powders

Moisture can catalyze degradation at high temperatures. Pre-drying the 3840 compound before processing can prevent hydrolytic reactions that increase MFI and reduce quality.

Case Study: High MFI vs. Low Melt Flow Index Behavior in Rotomolding

A comparison of two 3840-based formulations with different MFIs—one at 7.2 g/10min and another at 9.1 g/10min—under identical rotomolding conditions showed:

| Property | Low MFI (7.2) | High MFI (9.1) |

|---|---|---|

| Wall Uniformity | Good | Excellent |

| Cycle Time | Slightly longer | Shorter |

| Impact Resistance | High | Moderate |

| Surface Finish | Matte | Glossy but with micro-defects |

| Post-processing deformation | Minimal | Noticeable under heat |

The data suggests that while a slightly higher Melt Flow Index improves mold filling and reduces cycle time, it can negatively affect strength and surface stability. Therefore, staying within the optimal range and monitoring process variables is critical.

Conclusion

Optimizing the Melt Flow Index in 3840 polyethylene compounds is a balancing act between process efficiency and mechanical integrity. As rotomolding applications demand increasingly durable and complex components, controlling MFI—especially at high temperatures—is more important than ever.

By integrating stabilizers, fine-tuning process parameters, and using engineered formulations, manufacturers can achieve consistent results while reducing material waste and improving overall product quality.